Swiss Screw Machining Capabilities

Core Competencies :

For over 60 years SGP has been providing effective solutions to our customer’s manufacturing challenges. Our solutions are based on creative craftsmanship and extraordinary machining skills applied to our customer’s parts that include:

- Parts: Up to 1.25” diameter

- Production: Short and long run

- Performance: Tight tolerance/On-time

- Alloys: Wide Array Including Exotics

- Inventory Control: Flexible Stocking Programs – JIT Delivery

- Quality Control: ISO Certified System/SPC Data Services/Dock-to Stock Programs

On-Time Delivery:

Efficient manufacturing capabilities, an experienced workforce and resourceful, responsive service enable us to deliver your parts where and when you need them.

Star Glo Precision, LLC. can make this promise because of our flexible processes and experience in customer requirement planning that comes from a 60 year history of satisfying clients, no matter how exact the specs or how tight the deadline.

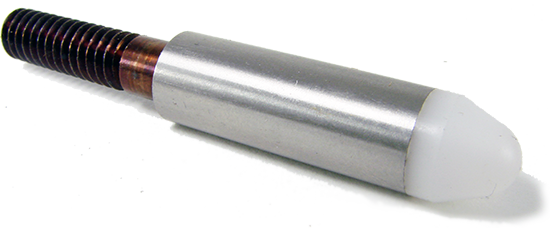

CNC Swiss Machining:

Machining of complicated components in a variety of materials including exotics is accomplished on 10 State-of-the Art STAR CNC 7-Axis Swiss Screw Machines. Live tooling and capacity to 1.25″ diameter allows SGP to produce your most exacting Swiss screw machining components from Prototype/Pre-Production/Full Production.

Conventional CNC Turning and Milling:

A full department of conventional CNC Turning and Milling equipment is available to support our Swiss division. This includes Vertical Machining Centers up to 20” x 40” capacity and CNC Turning to 6” in diameter.

GET IN TOUCH

Star Glo Precision, LLC145 Commerce Rd.

Carlstadt, NJ 07072

ATTN: Jerry Palanzo Jr

P: 203-743-5525 ext 111

Email: gpalanzo@starglo.com

STATEMENT OF LIMITED LIABILITY

THE BUYER OF CONTRACT MANUFACTURING SERVICES FROM THE SELLER (Star Glo PRECISION LLC), UNDERSTANDS THAT EVEN AFTER IMPLEMENTING ALL THE MANUFACTURING AND INSPECTION METHODS KNOWN TO THE SELLER, RISKS STILL REMAIN IN THE PRODUCTION/ASSEMBLY OF CUSTOM COMPONENTS. THE BUYER THEREFORE AGREES THAT SELLER’S LIABILITY SHALL NOT EXCEED THE AMOUNT OF THE CHARGES FOR THE PURCHASED COMPONENT. THE BUYER AGREES AND UNDERSTANDS THAT THIS LIMITATION OF LIABILITY IS NOT AN EXCULPATORY CLAUSE. THE REIMBURSEMENT AND FULL LIABILITY OF THE SELLER SHALL NOT EXCEED THE AMOUNT OF THE CHARGES FOR THE WORK DONE BY THE SELLER IN PROVIDING CONTRACT MANUFACTURING SERVICES.

145 Commerce Rd., Carlstadt, NJ 07072

Ph: 203-743-5525 ext. 111 • Jerry Palanzo Jr — Email: gpalanzo@starglo.com

Copyright © Star Glo Precision, LLC. All rights reserved.

Site Designed and hosted by Design-2-Part Web Design.